Project: LoC Grid — Lenarduzzi & Wei

-

Intro

-

Technical Aspects

Information

| Primary software used | Python |

| Software version | 1.0 |

| Course | Computational Intelligence for Integrated Design |

| Primary subject | AI & ML |

| Secondary subject | Machine Learning |

| Level | Intermediate |

| Last updated | September 26, 2025 |

| Keywords |

Responsible

| Teachers | |

| Faculty |

Project: LoC Grid — Lenarduzzi & Wei 0/1

Project: LoC Grid — Lenarduzzi & Wei

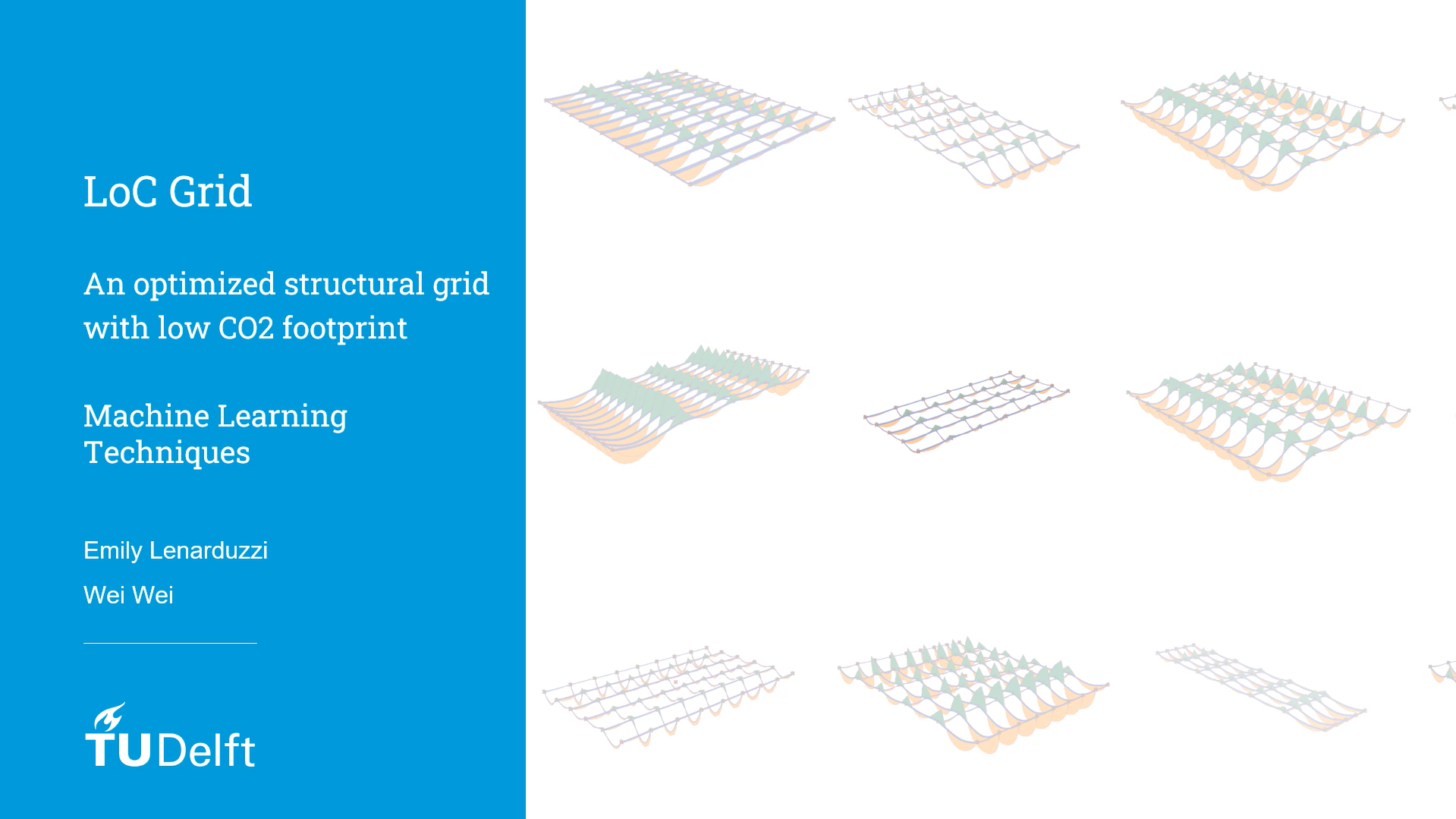

This project focuses on developing a surrogate model to predict the structural performance of a grid system and optimize the cross-sections of its members.

Structural elements in buildings – such as columns and beams – are typically made from carbon-intensive materials like concrete and steel. To build more sustainably, it is essential to optimize structural systems by minimizing material usage while maintaining sufficient structural performance.

This project focuses on developing a surrogate model to predict the structural performance of a grid system and optimize the cross-sections of its members. Compared to conventional structural analysis tools like Karamba3D, the surrogate model is far less computationally intensive, allowing designers to quickly evaluate and compare multiple design options.

Project Information

- title: LoC Grid

- Author(s): Emily Lenarduzzi, Wei Wei

- Year: 2024

- Keywords: neural networks, regression, classification, surrogate model

- Topic tags: structural optimization, embodied carbon

Project: LoC Grid — Lenarduzzi & Wei 1/1

Technical Aspectslink copied

Design Workflow

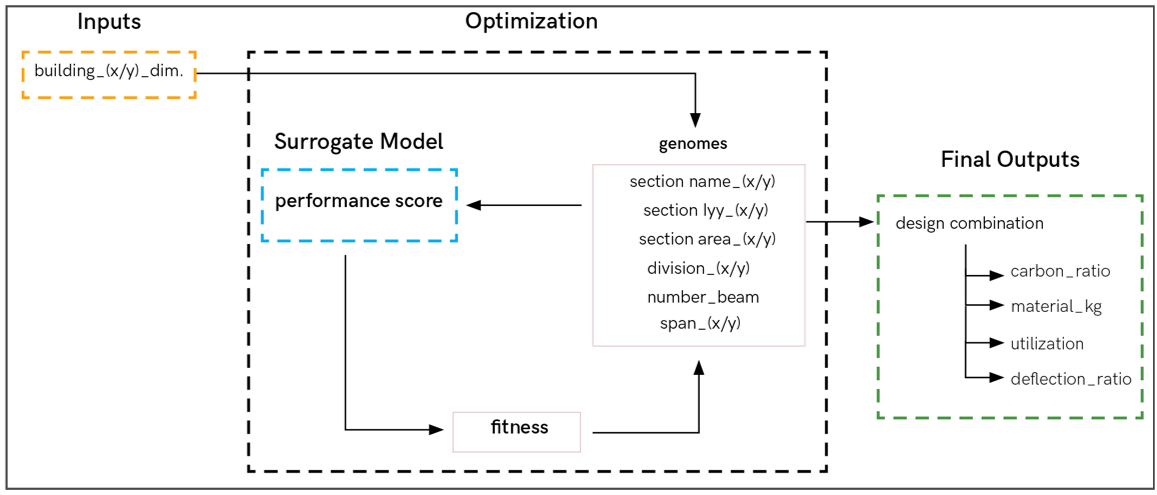

This project aims to assist designers in evaluating structural system performance during the early design stages. Given a structural grid and initial cross-section selection, the algorithm predicts a performance score based on utilization, deflection, material usage, and embodied carbon metrics.

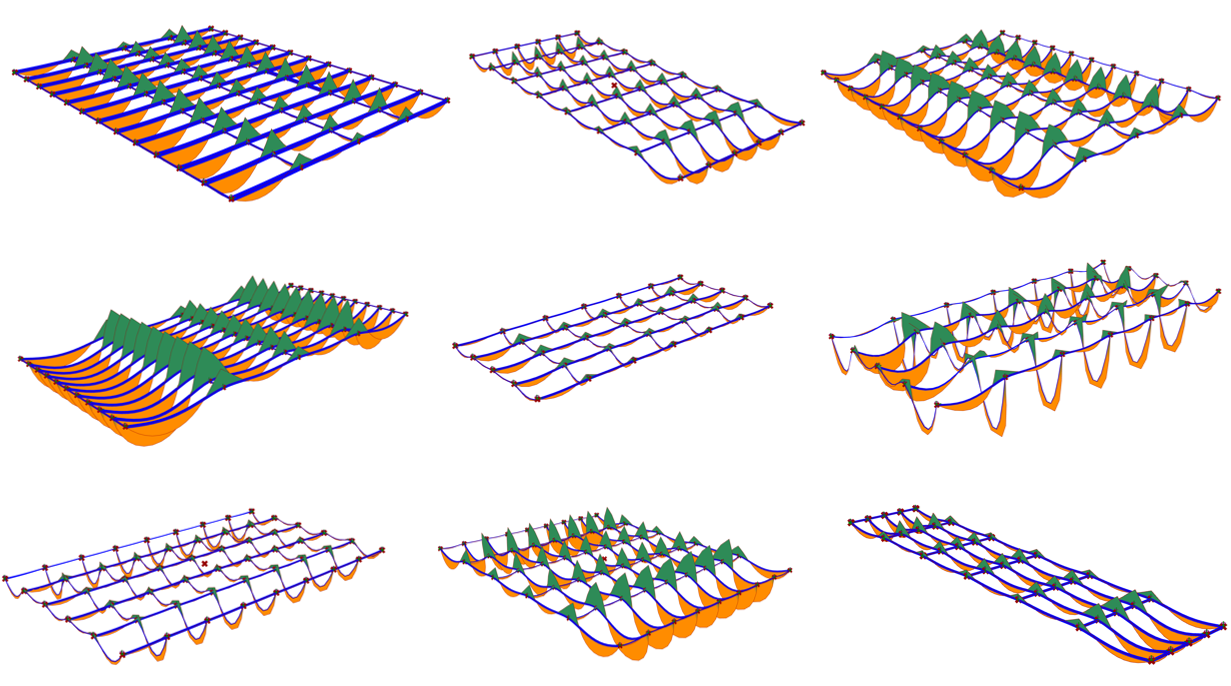

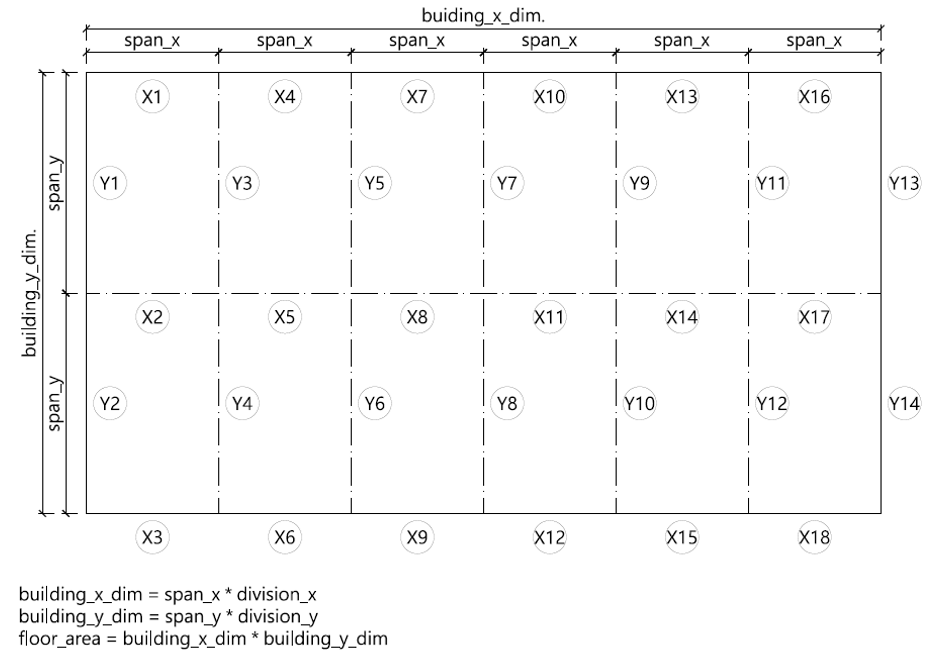

The algorithm is trained on a dataset generated from a parametric rectangular grid system, modelled in Grasshopper. The dataset includes the input geometric parameters of the grid system, including grid size, division, total floor area, material properties, and cross-sections. And the corresponding structural analysis outputs of utilization, deflection, and material usage. The materials were limited to S235 steel, and cross-sections were restricted to 18 IPE variants to reduce the complexity of the design space.

Machine Learning Workflow

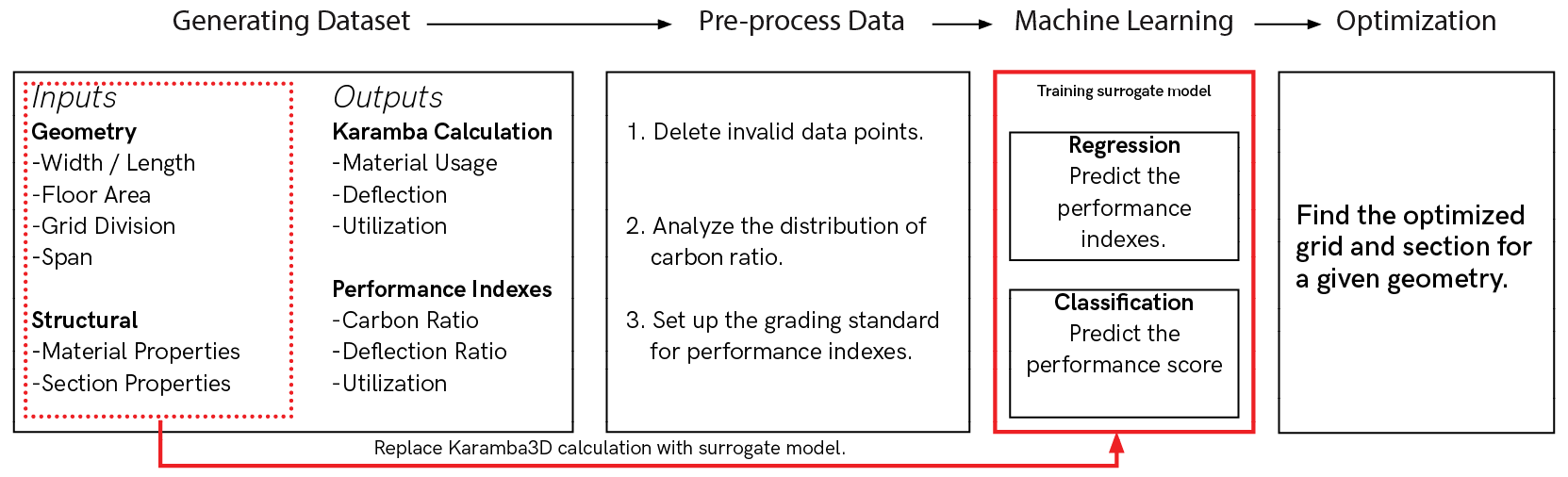

The objective of training a machine learning model was to predict the structural performance from the given input variables without any time-consuming analysis in Karamba3D.

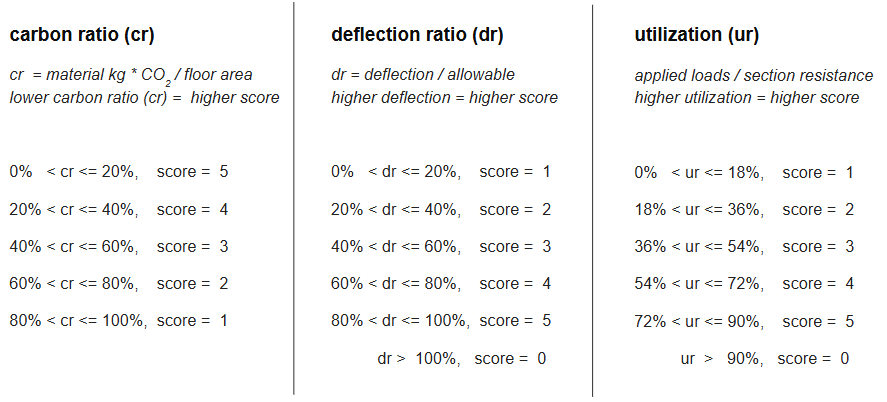

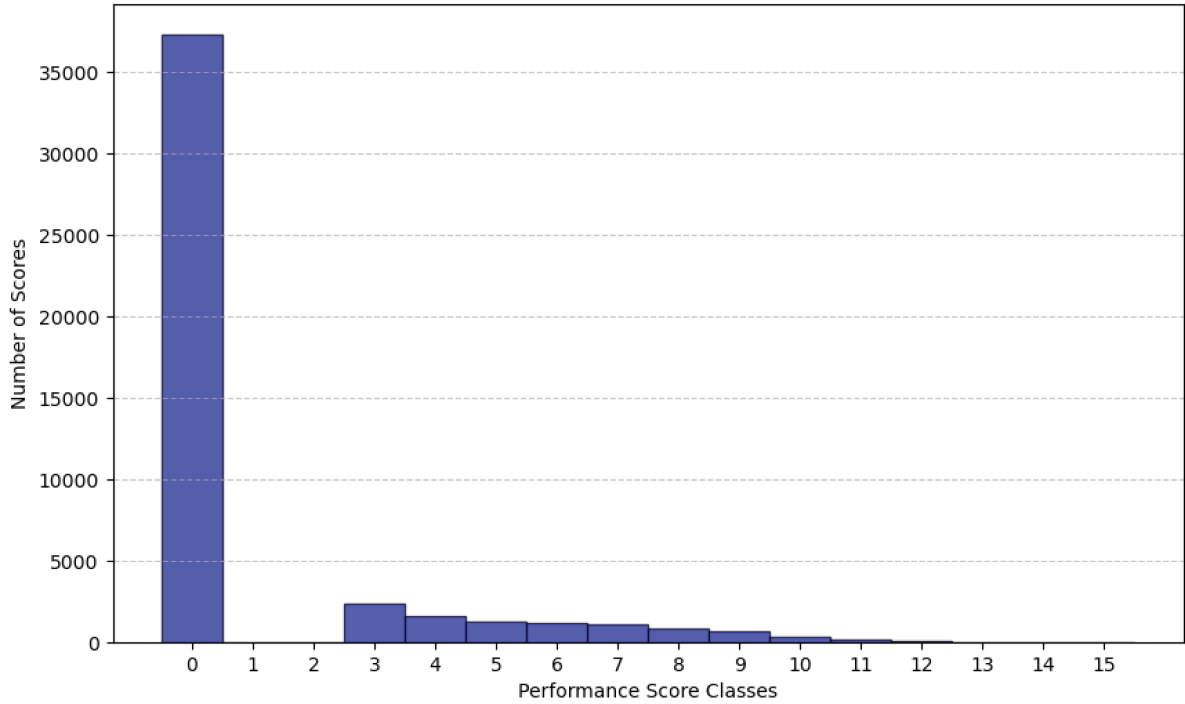

A rating system was used to evaluate the performance of each grid design. Utilization and deflection ratios were maximized within regulatory limits to avoid over-dimensioning, while material usage was minimized to optimize material efficiency and reduce environmental impact. Each design option is assigned a final performance score, from zero to fifteen, representing the combined sum of the carbon ratio, deflection ratio and utilization ratio.

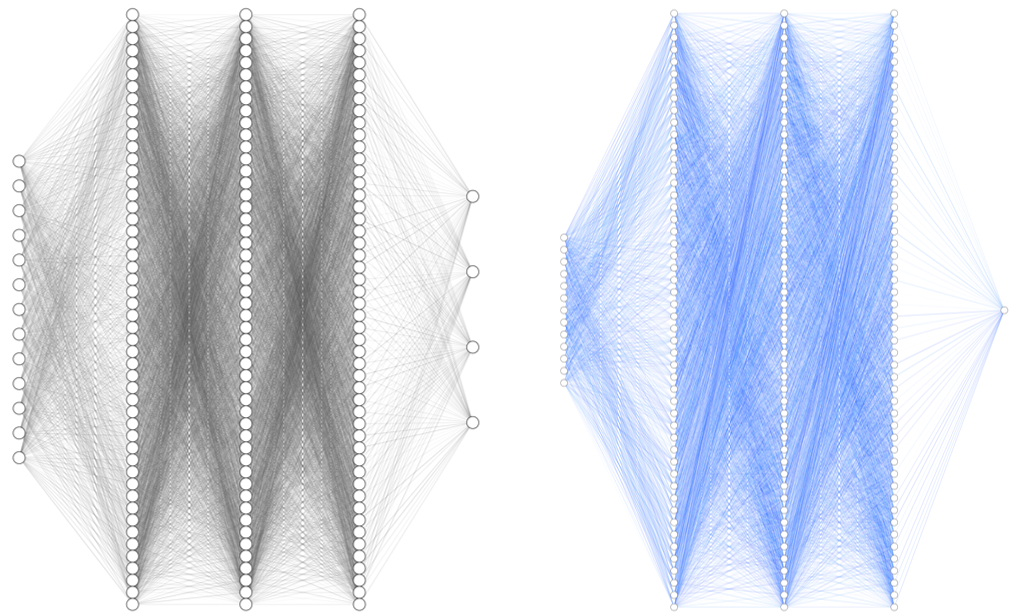

The machine learning workflow applies supervised learning techniques, where the model is trained from labelled input and output data. An essential step was pre-processing the dataset. This involved removing the invalid data points to prevent errors and normalizing the structural analysis outputs to improve training accuracy.

Regression was used as an initial ML technique to predict the actual utilization, deflection, and material usage values for each design option, thus avoiding the time intensity involved in structural analysis calculations. However, this technique only outputs the predicted values but did not provide any indication of the optimal solution or ranking of the solutions within the design space.

Classification was then used to predict the overall performance score of each design, thus providing an effective way to rank the options within the design space. The classification model showed strong prediction results (97% prediction accuracy). However, within the dataset there was a disproportionate number of samples within each performance score class, leading to skewed prediction results.

Once trained, the algorithm was intended to be integrated into Grasshopper as a lightweight component, replacing the more computationally intensive Karamba3D analysis. However, due to Python compatibility limitations in Rhino 7, integration of the surrogate model within the Grasshopper workspace remains to be solved.

Software & Plug-ins:

- Rhino 7 and Grasshopper for parametric dataset generation

- Karamba3D for structural analysis

- Jupyter Notebook for Python script development

- scikit-learn, MLPRegressor and MLPClassifier for machine learning models

Write your feedback.

Write your feedback on "Project: LoC Grid — Lenarduzzi & Wei"".

If you're providing a specific feedback to a part of the chapter, mention which part (text, image, or video) that you have specific feedback for."Thank your for your feedback.

Your feedback has been submitted successfully and is now awaiting review. We appreciate your input and will ensure it aligns with our guidelines before it’s published.