MO Façade Optimisation – Design Explorer Analysis

-

Intro

-

Hypothetical case

-

Clear Prioritization

-

No Clear Prioritization

-

Conclusion

-

Useful Links

Information

| Primary software used | Grasshopper |

| Course | MO Façade Optimisation – Design Explorer Analysis |

| Primary subject | AI & ML |

| Secondary subject | Optimization |

| Level | Intermediate |

| Last updated | November 27, 2024 |

| Keywords |

Responsible

| Teachers | |

| Faculty |

MO Façade Optimisation – Design Explorer Analysis 0/5

MO Façade Optimisation – Design Explorer Analysis

Explanatoin of using design explorer to analyse optimization results for research purposes.

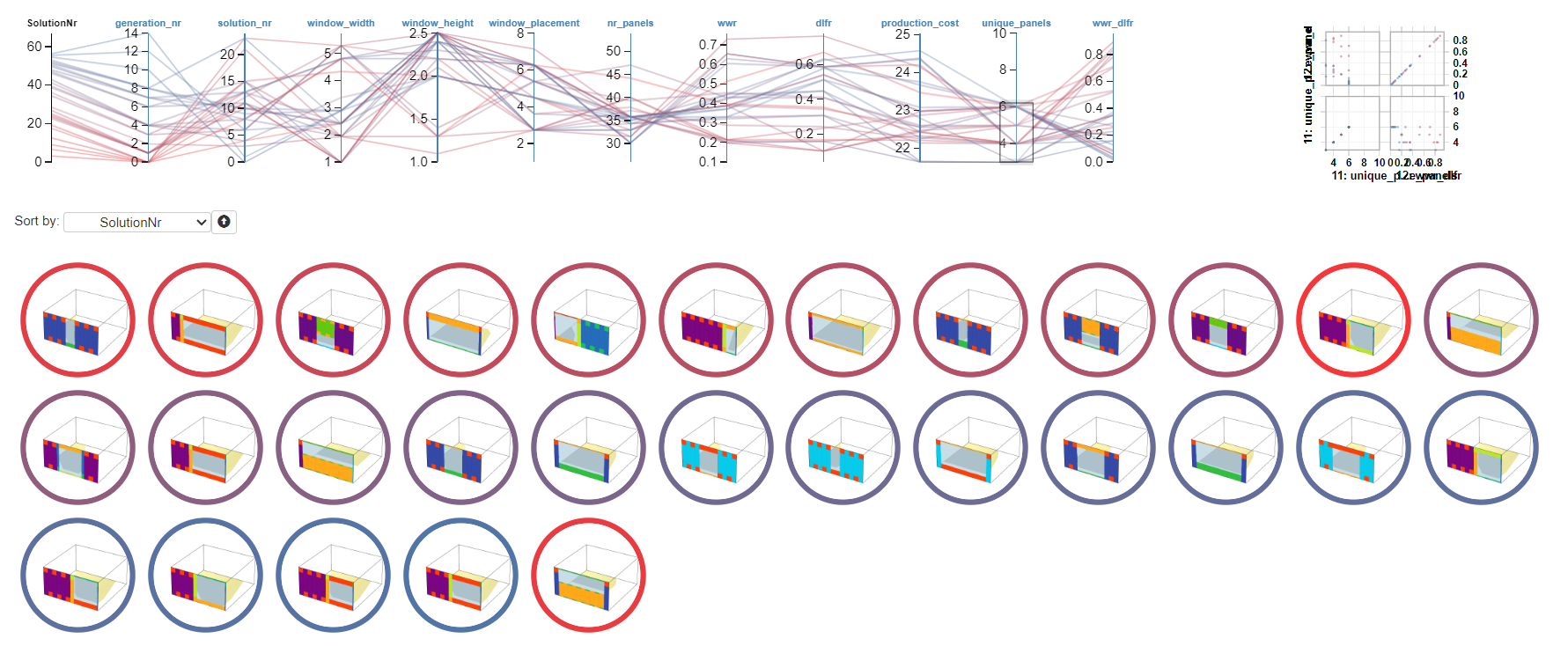

There are several ways to analyse the results of a multi-objective optimization that was set up using Wallacei. One method is to export your results to Design Builder and use the parallel coordinate plot to further filter the options. In this tutorial we will discuss some strategies for how to narrow down the selection of design options.

Remember that there is no one single optimal solution in multi-objective optimization. There will always be a trade-off between different objectives. To help narrow down a solution, you can filter the different options using brushing, discussed earlier in the tutorial.

In this optimization, there were 3 objectives which should all be minimized:

- The production cost

- The number of unique panels

- The distance to the domain for the Window-Wall Ratio (WWR) and the distance to the optimal value of the optimal direct light area to floor ratio (DRFL). This combines both factors while keeping them near their optimal value. This will also be referred to as the performance.

Let’s look at two scenarios and how you can use brushing to find a solution.

MO Façade Optimisation – Design Explorer Analysis 1/5

Hypothetical caselink copied

For this tutorial, we use a hypothetical case. Please note that the case is not supported by actual scientific information. It is merely an example that includes dummy information, to let you perform the computational workflow on a very simple case. (If you are following this tutorial because you are attending the course BK3WV4, in BK3WV4 you will make real literature review to set a well-grounded scientific framework of information). In this hypothetical case, assume you are researching factors that affect the production footprint of a façade. Assume that in this research, one of your research questions is:

Which window parameters have the highest impact on the production footprint of a façade for a residential studio apartment design, while ensuring adequate lighting.

Assume you have already performed a literature review about this subject. Assume that based on literature review you have decided to focus on an average residential studio design with 1 window on 1 façade. Assume that typical dimension for an average studio is (please note, this is dummy information):

- Room width = 6m

- Room depth = 6m

- Room height = 3m

Assume that based on literature review you have identified two factors that you want to focus on, as relevant for the production footprint. Both factors influence the level of efficiency, packaging material, and waste streams, and therefore the production footprint. These two factors are (please note, this is dummy information):

- The production cost, with a penalty for panel sizes that are produced in small amounts and a reduction in cost for panel sizes that can be produced in bulk.

- The number of unique panels (because for each unique panel new production features must be implemented).

Finally, assume that based on literature review you have figured out that to reach adequate lighting the window to wall ratio (WWR) should be between the range of 30-70%. Additionally, extensive direct lighting should be avoided while remaining at a minimum. It is preferred to have a direct light to floor ratio as close to 60% as possible on the summer solstice at noon. Both factors influence the internal climate and sustainability aspects, such as: overheating, and energy use.

Based on the hypothetical case described above, in this tutorial we will create a grasshopper definition for façade panelization. We will consider the case of a façade with one window. We are going to optimize that façade panels pattern to achieve various goals, like minimum overall cost, for example. By running an optimization, we can investigate the pareto front to get insights on which parameters have the highest impact on the production footprint of the façade panels. With this information we can identify the following parameters, variables, and objectives for the optimization model:

Parameters:

- Room dimensions

Variables:

- Window size

- Window positioning

Objectives:

- Minimal production cost

- Minimum number of unique panels

- Window to wall ratio between 30-50%

- Direct light area to floor ratio optimum of 60%

MO Façade Optimisation – Design Explorer Analysis 2/5

Clear Prioritizationlink copied

In some cases, there may be a clear direction on how to prioritize and filter the objectives. Let’s say that the factory which is producing the panels is busy and they have informed the contractor that producing more than six unique panels for your project would require too many machines so production. They explain that if your project needs too many machines, your project would not be able to be scheduled for several months until some of the existing projects in production are complete. This longer timeframe significantly delays your project. The owner needs the project completed as soon as possible because they will lose money each day the project is delayed and therefore not open.

In this case, there is a clear direction that states one factor is more important than the others. We can use brushing to first filter the selection to only designs that use six or fewer unique panels.

We also know that the closer the WWR and DRFL values are to the recommended value, the better the performance of the space is. Therefore, we can add a second filter to get results that have this objective value be between 0 and 0.2.

After applying these two filters, it is possible to further compare the remaining design options. In this case, the different design options also vary greatly in the cost. This allows for several paths that can be taken to further narrow down the options:

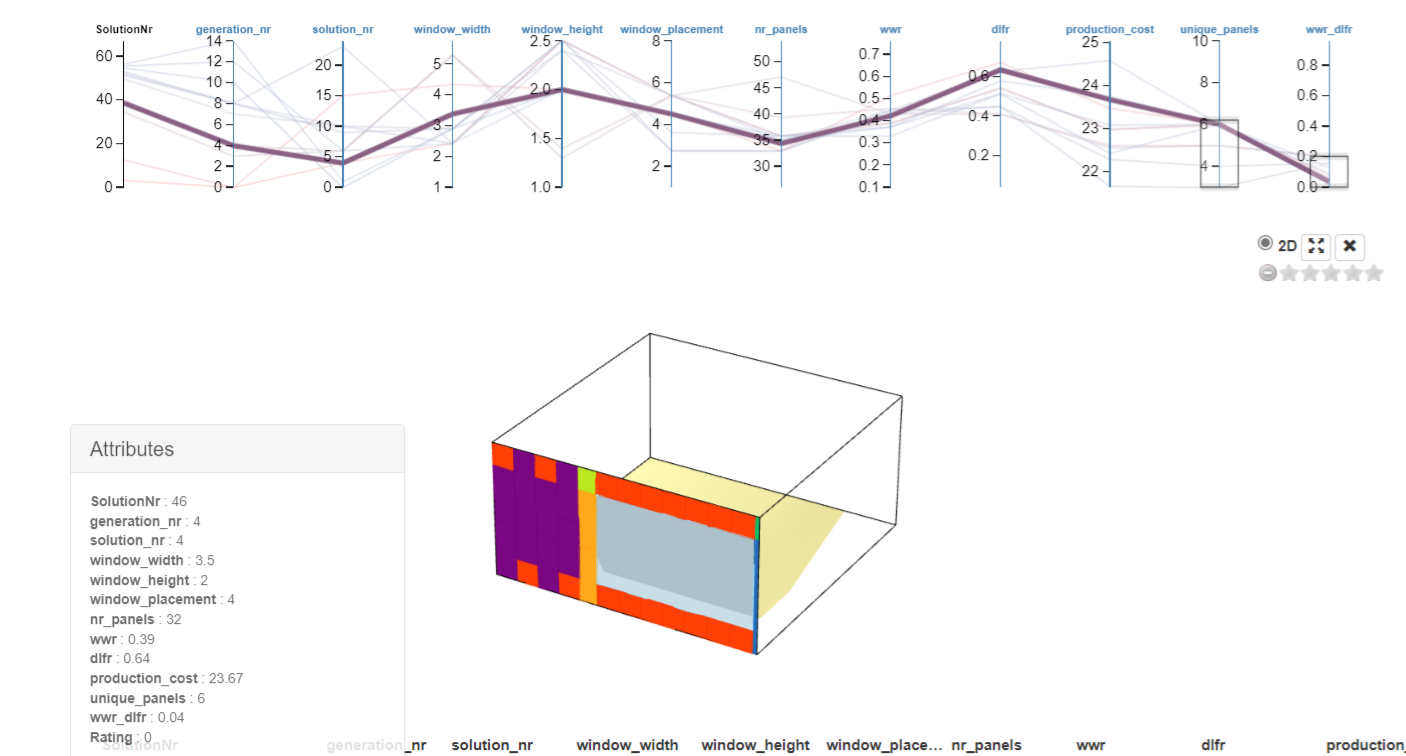

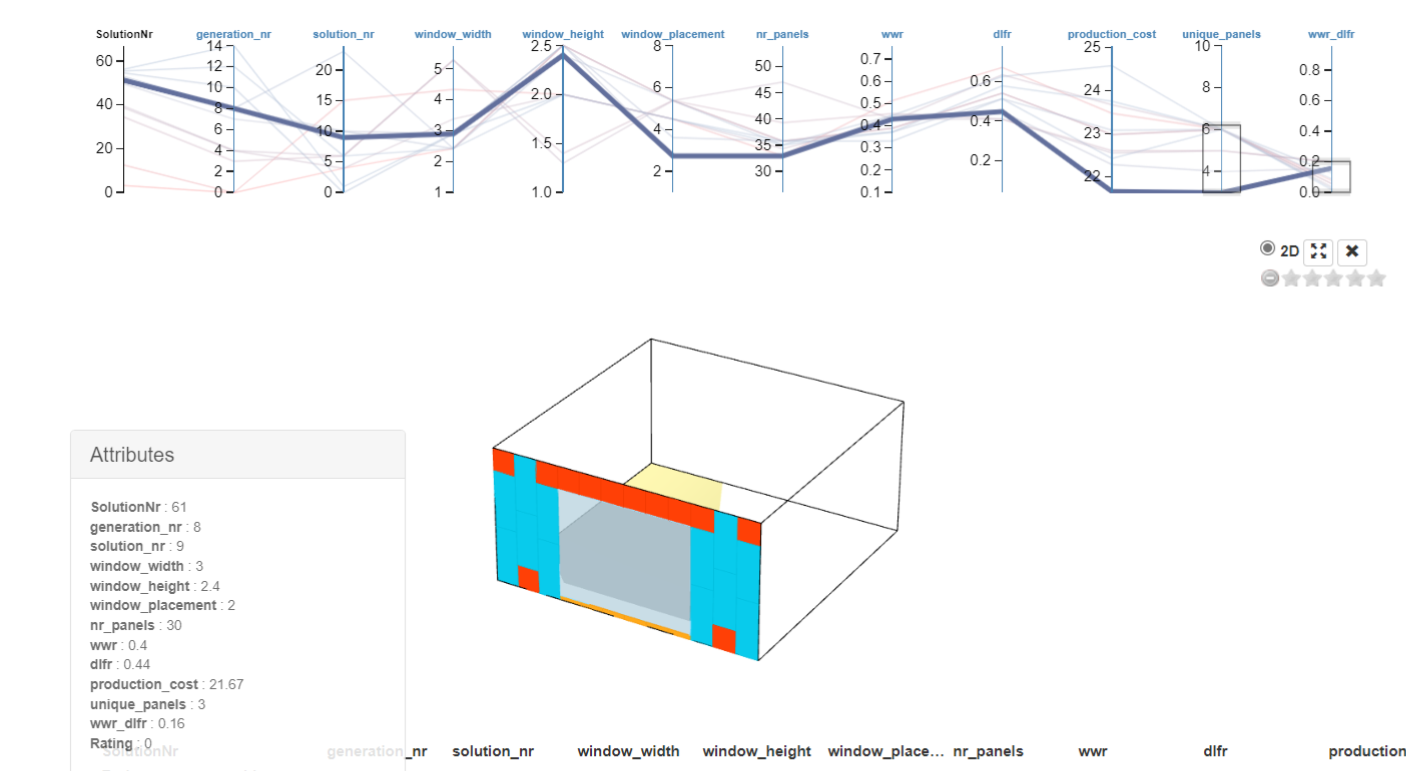

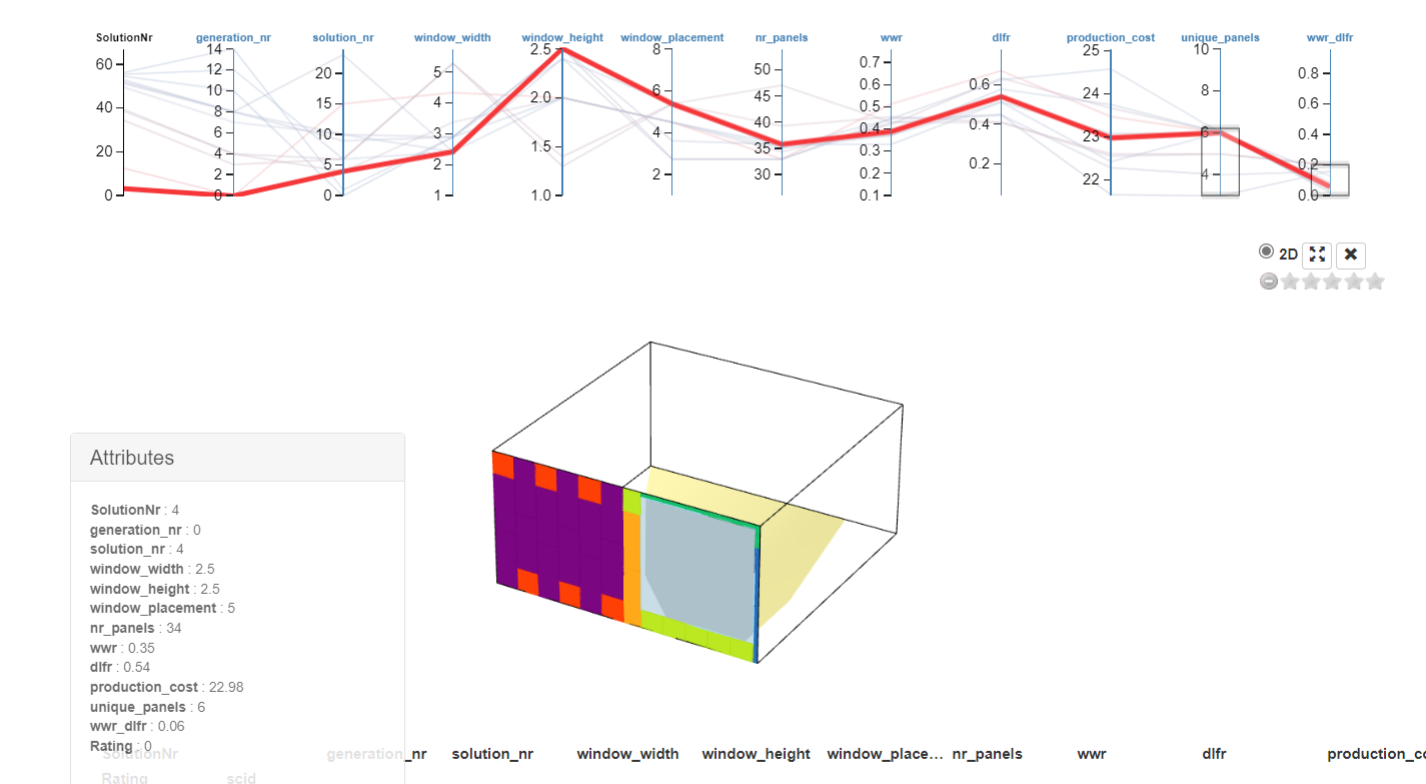

- Choose the best performing (Image 48). This option is on the higher end on the pricing so this trade-off would need to be evaluated. There are some cases in which energy costs may impact the decision. If this is the case, the design’s impact on energy use could be calculated to see if the trade-off saves energy costs during the building’s lifetime.

Choose the lowest production cost option (Image 49). This option has a lower performance in the WWR_DRFL factor than the others, but we also already filtered this objective to have a range of successful choices. Therefore, going with the lowest cost option can be worth a slightly lower performance. We can see between the choice of best performing from Option 1 and lowest cost Option 2, there is a trend that the higher the cost, the better the performance is of the design.

Choose an option that balances cost and performance (Image 50). Based on recognizing that the cost and performance generally have an inverse relationship, it is possible to also select an option that compromises on both points. There is a design option that is in the middle of the range for cost and the middle of the filtered range for the WRR_DRFL objective.

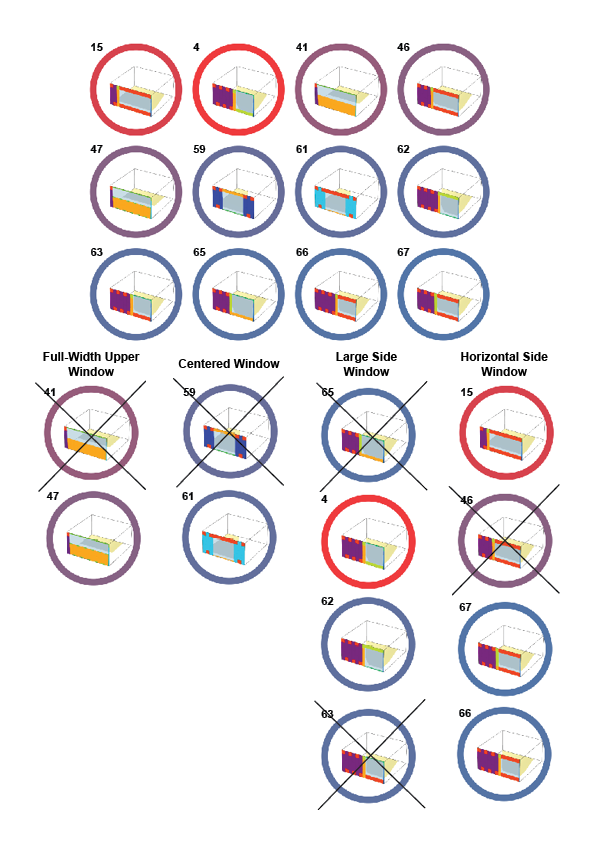

Choose an option based on aesthetics. Group the designs by aesthetics and further narrow down and select options (Image 51). Since the options have been narrowed down by the different objectives already, it’s possible to incorporate aesthetics into the decision-making process. You cannot group the designs by aesthetics in Design Explorer, however if you note the design and its solution number, you can track them and sort them by aesthetics. Then based on each design, you can further narrow down the options as some may be redundant.

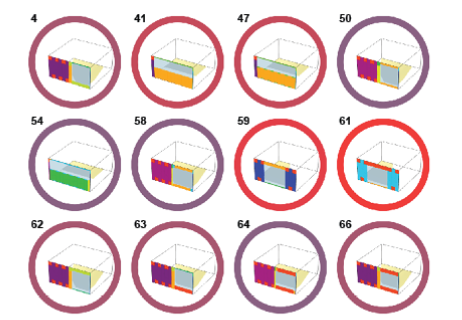

Example of Reviewing Options Based on Aesthetics

Let’s walk through an example of how you can review the options based on the design. In this case, there are some designs that are very similar. Based on the similarities it is possible to group them into four categories: full-width upper window designs, centred window designs, large side window designs, and horizontal side window designs. To compare the following options, it is necessary to click on different designs based on their solution number and compare them. This is because in Design Explorer, you cannot filter by a list you enter like a list of specific solution numbers.

Narrowing down some of the options might be simple. For example, of the full-width upper window designs, 47 has slightly lower cost than 41 and the other objectives have the same result. Therefore, option 41 can be eliminated. Of the centred window designs, 61 has a lower production cost than 59 and the other objectives have the same result. Therefore, 59 can be eliminated.

In other cases, it may only be possible to narrow down to a few options. Of the large side window designs, 4 and 62 have the same objective values because the window is just aligned to the top on one design and to the bottom at the other. However, they have different aesthetics as the alignment of the window changes the look of the building. 63 and 62 both have mid-range cost and mid-range WWR_DRFL values. Since options 62 and 63 have very similar results, it is possible to remove 63 since it does not add anything to the options. 65 has a higher cost but lower WWR_DRFL. You can also eliminate 65 because it has a similar aesthetic and performance to 4, and 4 has a lower cost.

Of the horizontal side window designs, 15 and 67 have very similar objective values with both having a cost in the middle of the range and a WWR_DLFR in the middle of the filtered range, however they have noticeably different aesthetics. The window in design 15 spans almost the entire room while the window in 67 only spans half the room. 46 and 67 have similar objective values and have similar aesthetics. Therefore, it is possible to eliminate 46 since it does not add anything to the options. This narrows the category down to 3 options which have a range of aesthetics from an almost full-width window to a mid-width window, to a narrow window and they each have different trade-offs between the objective values.

As you can see, reviewing a multi-objective optimization problem can lead you to several results. By evaluating and prioritizing the objectives, you can compare options to make more informed decisions. You can also analyse relationships. In the example discussed, there was an inverse relationship between the production cost and performance of the WWR_DLFR objective when looking at designs that have 6 or fewer unique panels.

MO Façade Optimisation – Design Explorer Analysis 3/5

No Clear Prioritizationlink copied

In other cases, there may be no clear direction on how to prioritize and filter the objectives. In this case, we can be guided by optimizing each objective. In this case, we know that we want to minimize all three objectives, therefore we can start by using brushing to filter to a smaller range of options.

- We will filter the production cost to a range of 21.5 to 23.5.

- We will filter the number of panels to a range of 3 to 7.

- We will filter the WWR_ DRFL objective to a range of 0.0 to 0.2.

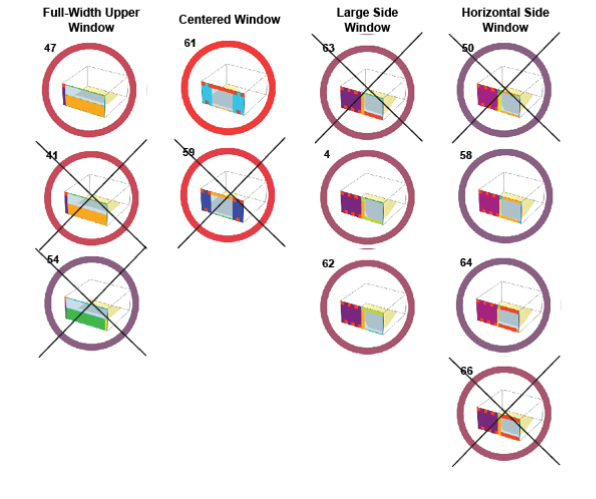

This already narrows down the designs to 12 options.

From this narrower filter it is of course possible to select a design with the lowest value in one of the three objectives, a design that balances all three objectives or a combination of two of the objects, or a design that meets the design intention of the project. It is also possible to group the designs based on design characteristics.

It is possible to group the remaining options by aesthetics like Step 5 of the previous section. We can use the same four categories: full-width upper window designs, centred window designs, large side window designs, and horizontal side window designs.

For the full-width upper window designs, the cost between 47, 41, and 64 are similar and the performance is the same. 47 has a lower cost while also reducing the number of unique panels, therefore it is a good choice in this category. For the centred window designs, 61 has lower cost and fewer unique panels than 59, therefore it is a logical selection.

When reviewing the large side window designs, 4 and 62 perform slightly better than 63 in the cost and performance, therefore 63 can be removed as an option. 4 and 62 are inverse designs of each other with one having the window aligned to the top of the room and the other having it aligned to the bottom of the room. For this reason, it is logical to keep them both in the selection

Finally, when looking at the large side window designs it is also possible to remove some options. When comparing 50 and 58, 58 has better performance and a lower cost. When comparing 64 and 66, 64 also has better performance and a lower cost.

NOTE: In this example, we expanded the range of the filter when selecting the number of unique panels. This means that the inverse relationship between production cost and performance which we noticed when we looked at a maximum of 6 unique panels, is no longer applicable. In this case, 58 and 64 improve on both these points when compared with similar designs. This is why it is important to carefully track and write down the filters you use and always quantify your observations. Noticing that there is an inverse relationship between production cost and performance is not true for the set of all results. Noticing that there is an inverse relationship between production cost and performance for designs that use 6 or fewer unique panels is true.

Using the noted steps, already narrows down the options to six options each of which have different design implications. When reviewing these six options, you can either decide or present the options to a client so they can provide further input. If deciding, it will be possible to select:

- A design with the lowest value in one of the three objective

- OR a design that balances all three objectives (or a combination of two objectives)

- OR a design that meets the design intent of the project

Sometimes it can also help to model the design at a larger scale to see the impact to the entire building. In this case, it would be a good idea to model the façade of the whole building based on the selected option(s) to see how it impacts the overall design.

MO Façade Optimisation – Design Explorer Analysis 4/5

Conclusionlink copied

Congratulations on completing this tutorial! Now, you’re equipped not only to optimize data but also to visualize all potential solutions and choose the one that best meets your goals. You’ve learned how to extract data, including images, from Wallacei and Grasshopper and turn it into a .CSV file using the Colibri plugin. You also explored two methods for importing data into Design Explorer, depending on whether your .CSV file includes images. Finally, you gained skills in reading, analysing, and filtering solutions in Design Explorer. With this knowledge, you’re now ready to visualize all your options and make informed choices based on your objectives. Take it further by experimenting with your own data—explore, analyse, and find the solutions that work best for you!

MO Façade Optimisation – Design Explorer Analysis 5/5

Useful Linkslink copied

Linked tutorials

Other useful links

Write your feedback.

Write your feedback on "MO Façade Optimisation – Design Explorer Analysis"".

If you're providing a specific feedback to a part of the chapter, mention which part (text, image, or video) that you have specific feedback for."Thank your for your feedback.

Your feedback has been submitted successfully and is now awaiting review. We appreciate your input and will ensure it aligns with our guidelines before it’s published.